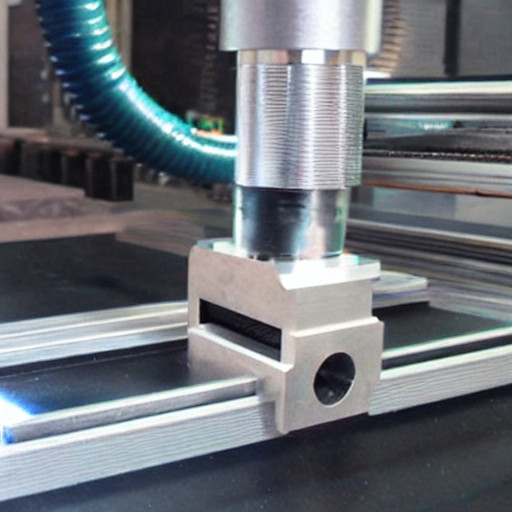

In the realm of manufacturing, precision is paramount. From aerospace components to intricate medical devices, industries rely on CNC (Computer Numerical Control) machining for impeccable accuracy and efficiency. This article delves into the cutting-edge innovations that are reshaping the landscape of cnc machining solutions, paving the way for unprecedented levels of precision and performance.

The Evolution of CNC Machining:

CNC machining has come a long way since its inception. Originally developed in the 1940s and 1950s, early CNC machines were rudimentary compared to today's advanced systems. The evolution of computer technology and automation has propelled CNC machining into a realm of unparalleled precision and speed.

Advancements in Tooling Technology:

One of the cornerstones of CNC machining is the tools used to shape raw materials into finished products. Recent advancements in tooling technology have revolutionized the capabilities of CNC machines. From high-speed cutting tools to specialized coatings that enhance durability and performance, manufacturers now have access to a wide array of cutting-edge tools that enable intricate designs and tight tolerances.

Integration of AI and Machine Learning:

Artificial intelligence (AI) and machine learning algorithms are increasingly being integrated into CNC machining systems. These technologies optimize tool paths, predict potential issues before they arise, and adapt machining parameters in real-time to ensure optimal performance. By harnessing the power of AI, manufacturers can achieve higher levels of efficiency and consistency in their machining processes.

Enhanced Control Systems:

Modern CNC machines boast highly sophisticated control systems that offer unprecedented levels of precision and flexibility. Advanced control interfaces allow operators to fine-tune machining parameters with ease, while real-time monitoring capabilities enable proactive adjustments to optimize performance. These enhanced control systems empower manufacturers to achieve the exacting specifications demanded by today's industries.

CNC Machining Solutions:

In the competitive landscape of manufacturing, companies are constantly seeking innovative solutions to stay ahead of the curve. CNC machining solutions encompass a wide range of technologies and strategies aimed at maximizing efficiency, accuracy, and profitability. From optimized tool paths to predictive maintenance algorithms, these solutions enable manufacturers to streamline their operations and deliver superior results to their customers.

Conclusion:

In conclusion, the advancements in CNC machining technology are reshaping the manufacturing industry. From the integration of AI and machine learning to the evolution of tooling technology, these innovations are driving unprecedented levels of precision and efficiency. As companies continue to invest in CNC machining solutions, we can expect to see further enhancements that push the boundaries of what is possible in manufacturing. With precision as the cornerstone, CNC machining remains at the forefront of innovation, powering the creation of the intricate components that drive modern society forward.