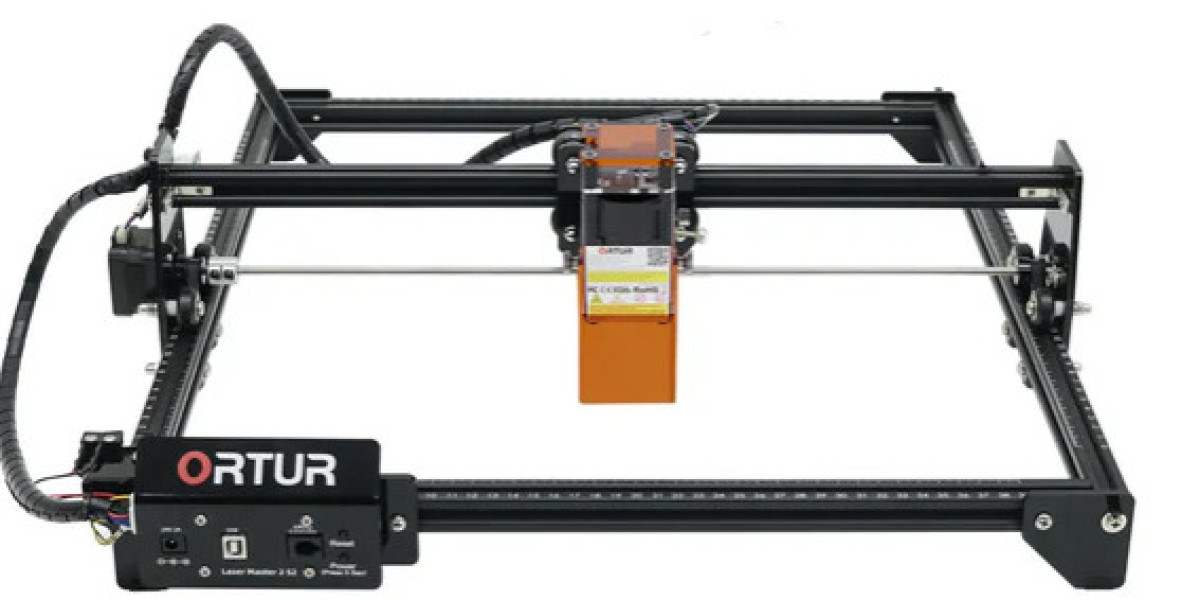

This article delves into the basic components of laser cutter parts machines, as well as our expert insights on care and maintenance. We also provide users with some practical considerations to ensure safety when using laser-cutting machines.

If you are considering investing in laser cutter parts technology, you should be familiar with its basic components. As experts in the field, we have taken care to provide a concise but valuable overview of each component that makes up a laser cutting machine, as well as its functions, benefits, and challenges.

The main components of the laser cutter parts machine

Understanding the main components of a laser cutting machine is just as important as learning what laser cutting is, as it can provide valuable insights into the complex work of the machine. By understanding the roles and interactions of components such as laser sources, optical systems, CNC controllers, tables, cutting heads, exhaust systems, cooling systems, and control panels, you can effectively maintain, troubleshoot, and maximize the performance of your laser cutting machine.

In addition, a thorough understanding of these core components is essential to ensure safe operation, optimize cutting accuracy, and extend the service life of the machine. So, let's directly explain each part of the laser cutter parts machine:

Laser source

The laser source is the core of the laser cutter parts machine. It produces a high-power laser beam to cut the material. There are two main types of laser sources used in laser cutting machines: CO2 lasers and fiber lasers. The components of a CO2 laser rely on a mixture of gases to produce the laser beam, while the components of a fiber laser use fiber doped with rare earth elements to produce the laser beam.

Optical system

The optical system consists of mirrors and lenses that precisely manipulate the laser beam and guide the laser beam onto the workpiece. The focusing lens is a key component of the optical system, ensuring that the laser beam is focused for fast cutting and high precision.

CNC controller

The numerical control controller, referred to as computer numerical control, is the brain of the laser cutter parts machine. It interprets design data and communicates with machine tools and laser sources that enable moving and cutting operations. The control system also controls the power supply to the laser. This helps control the output power of the laser.

workbench

The worktable provides a stable platform for the workpiece during the cutting process. It should be designed to withstand the heat and intensity of the laser without warping or affecting the precision of the cutting operation.

Cutting head

The cutting head of the laser cutter parts machine is used to deliver the laser beam to the workpiece. It usually includes a focusing lens and a nozzle to help expel the molten material. The cutting head usually has a servo motor to precisely control its movement.

Exhaust system

The exhaust system removes smoke, dirt, and debris from the cutting process, ensuring a spotless and safe working environment. Proper ventilation is essential to the health of the operator and the life of the laser cutter.

Cooling system

The cooling system prevents the laser source and other components from overheating during operation. It typically uses water or air to disperse heat and control the optimal operating temperature.

Control panel

The control panel allows the operator to enter cutting specifications, monitor the cutting process, and control the machine. It allows users to adjust settings, start cutting sequences, and troubleshoot.

Add-ons and accessories

In addition to learning the different parts of laser cutter parts machines, you must also consider the following parts and accessories that you may encounter when using such machines:

Safety function

Safety features such as emergency stop buttons, shields, and interlocking systems are essential to ensure the health of operators and bystanders. Adequate training and adherence to safety procedures are also critical.

Gas supply system

CO2 laser cutting machine parts also need attention. The gas supply system delivers the necessary gas mixture to the laser source. Maintaining proper gas pressure and purity is essential for the effective operation of laser cutter parts machines.

Laser beam alignment system

The laser beam alignment system is used to ensure accurate alignment of the laser beam with the optical system. Proper alignment is essential to achieve cutting accuracy.

Search

Popular Posts

-

Authenticity in the Bedroom: 4 Compelling Reasons to Embrace Real Orgasms

By Jim Peters

Authenticity in the Bedroom: 4 Compelling Reasons to Embrace Real Orgasms

By Jim Peters -

Unlocking Exclusive Aweber Special Offers: Elevate Your Email Marketing Strategy

By vreaubdsm

Unlocking Exclusive Aweber Special Offers: Elevate Your Email Marketing Strategy

By vreaubdsm -

Satta King Scandals and Controversies: Lessons in Responsible Gambling

Satta King Scandals and Controversies: Lessons in Responsible Gambling

-

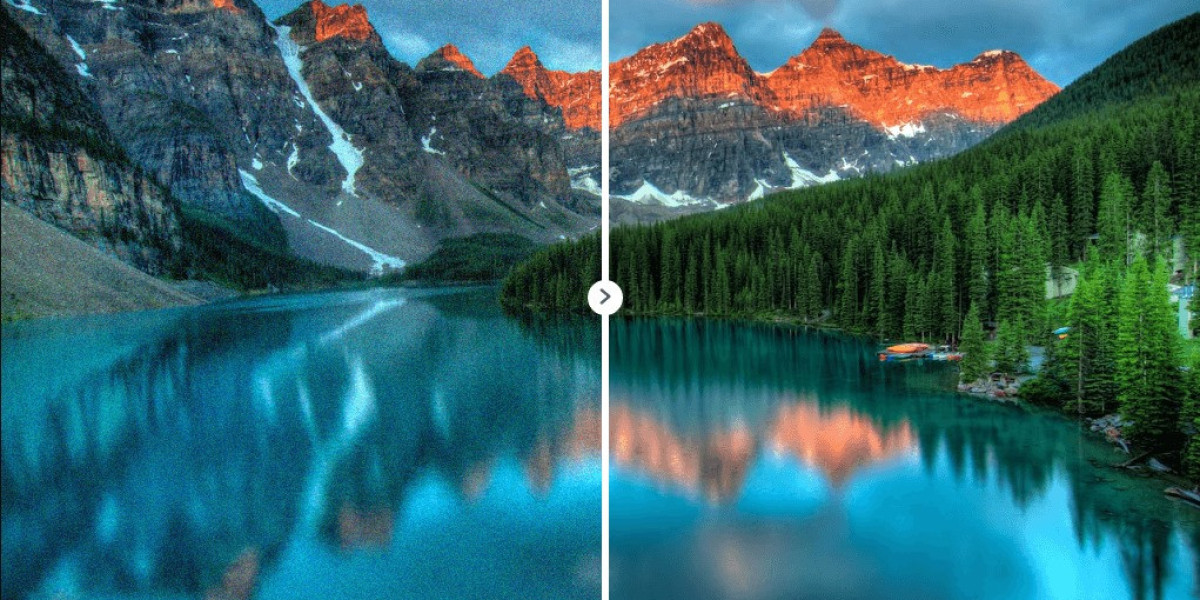

Unlocking Clarity: Unblur Images with AI Magic

By devil1o

Unlocking Clarity: Unblur Images with AI Magic

By devil1o -

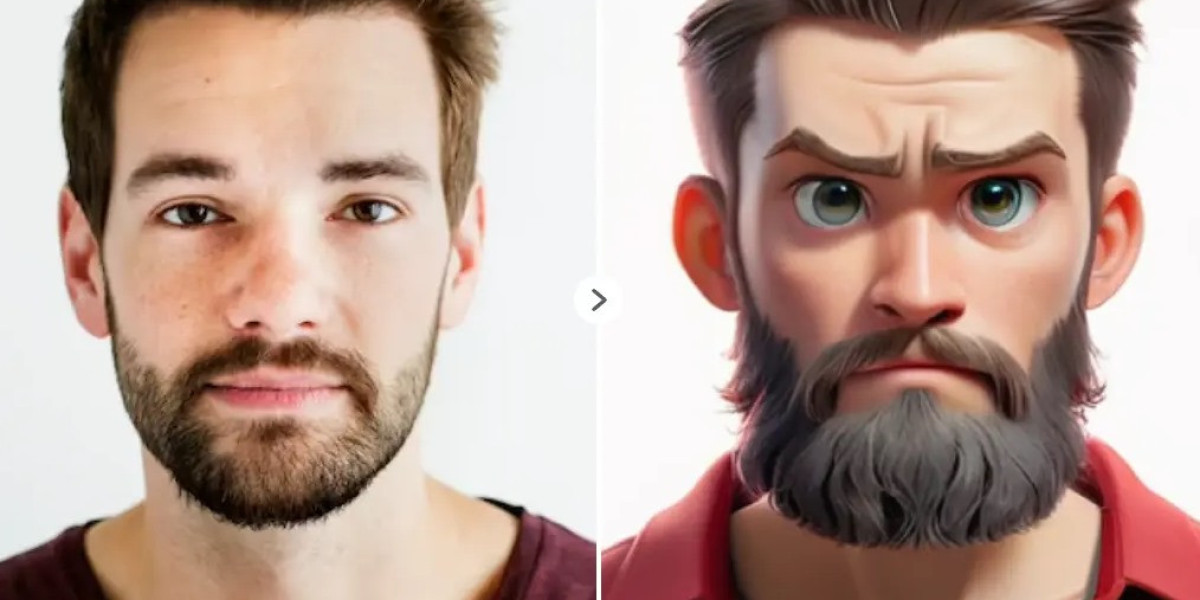

Discover the Magic of Photo to Cartoon AI Free Tools

By devil1o

Discover the Magic of Photo to Cartoon AI Free Tools

By devil1o