In the field of fluid handling and metering, low flow progressive cavity pumps are renowned for their efficiency and versatility. This article delves into the workings, benefits, and applications of these pumps, providing a comprehensive guide for anyone interested in understanding their pivotal role in various industries.

Understanding Progressive Cavity Pumps

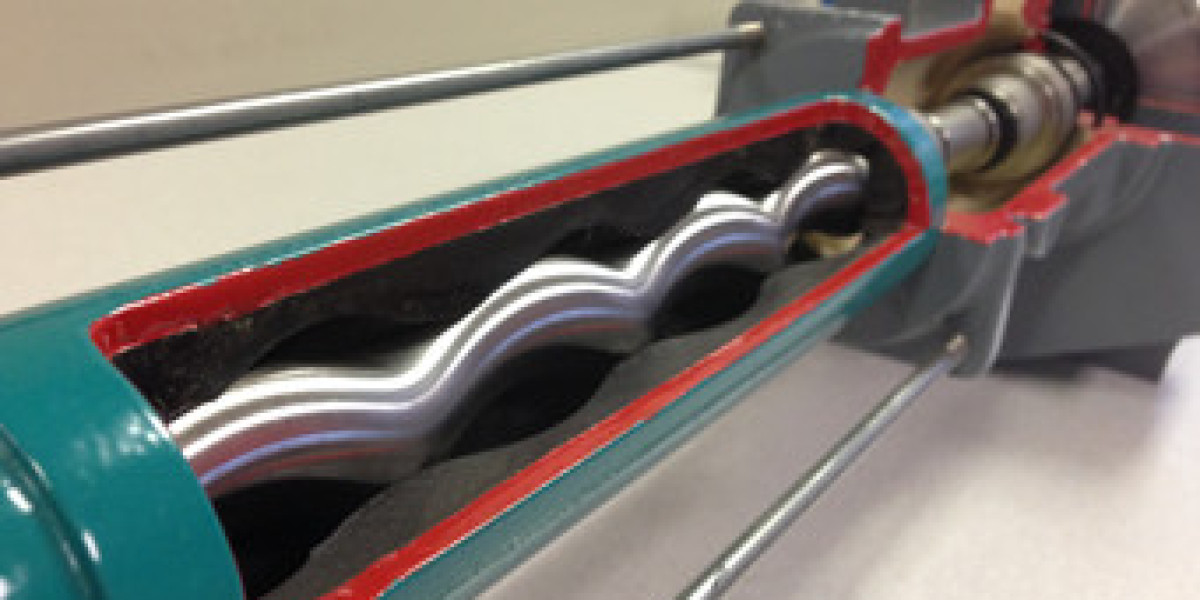

Progressive cavity pumps, also known as PC pumps, are positive displacement pumps that move fluid through a sequence of small, fixed-shape cavities. These cavities progress as the rotor turns within a stator, creating a smooth and consistent flow. This mechanism makes them particularly effective for handling viscous, shear-sensitive, and abrasive fluids.

How Low Flow Progressive Cavity Pumps Work

Low flow progressive cavity pumps operate on the same principle as their larger counterparts but are specifically designed for applications requiring precise flow control at lower volumes. Here’s a closer look at how they function:

- Rotor and Stator Interaction: The rotor, typically helical in shape, rotates within a double-helix stator, creating cavities that move fluid from the inlet to the outlet.

- Consistent Flow: The continuous movement of these cavities ensures a steady, pulsation-free flow, which is crucial for applications requiring precision.

- Handling Diverse Fluids: These pumps can handle a wide range of fluids, including those that are highly viscous, abrasive, or contain solids.

Benefits of Low Flow Progressive Cavity Pumps

There are several notable advantages to using low flow progressive cavity pumps:

- Precision: These pumps offer accurate flow control, making them ideal for dosing and metering applications.

- Versatility: They can handle a variety of fluids, from thin, watery substances to thick, viscous materials.

- Minimal Shear: The gentle pumping action minimizes shear, preserving the integrity of shear-sensitive fluids.

- Durability: Their robust design ensures long service life, even when handling abrasive or corrosive fluids.

Applications of Low Flow Progressive Cavity Pumps

These pumps are used in various industries due to their precision and reliability. Some common applications include:

- Chemical Processing: For accurate dosing of chemicals and additives.

- Food and Beverage: Handling viscous food products and ingredients with care.

- Pharmaceuticals: Precise metering of liquid medicines and other pharmaceutical products.

- Wastewater Treatment: Effective in dosing and transferring sludge and other waste materials.

- Oil and Gas: Used for injecting chemicals and other fluids in drilling and production processes.

Progressive Cavity Metering Pumps

Another crucial variant is the progressive cavity metering pump. These pumps are specifically designed for metering and dosing applications where precise flow control is paramount. They share the same operating principle as other PC pumps but are optimized for delivering accurate volumes over a wide range of flow rates.

Choosing the Right Pump

When selecting a low flow progressive cavity pump, several factors must be considered:

| Factor | Consideration |

|---|---|

| Fluid Characteristics | Viscosity, abrasiveness, and the presence of solids. |

| Flow Rate | The required precision and range of the flow rate. |

| Pressure Requirements | The operating pressure needed for the application. |

| Material Compatibility | Compatibility of the pump materials with the fluid being handled. |

Maintenance and Care

To ensure the longevity and optimal performance of your low flow progressive cavity pump, regular maintenance is crucial. Here are some tips:

- Regular Inspection: Check for wear and tear on the rotor and stator.

- Proper Lubrication: Ensure all moving parts are adequately lubricated to reduce friction.

- Cleaning: Clean the pump and associated systems regularly to prevent blockages and contamination.

- Prompt Repairs: Address any issues immediately to prevent further damage.

Low flow progressive cavity pumps and progressive cavity metering pumps are indispensable in industries requiring precise fluid handling. Their ability to manage a wide range of fluids with accuracy and consistency makes them a valuable asset. By understanding their operation, benefits, and maintenance needs, users can ensure optimal performance and longevity.

For high-quality low flow progressive cavity pumps, visit Mingjiepump. Discover how these pumps can meet your specific requirements and enhance your operations with reliable and efficient fluid handling solutions.

Explore our comprehensive range of progressive cavity metering pumps and find the perfect fit for your application at Mingjie Pump. Trust our expertise and technology to deliver the precision and performance you need.