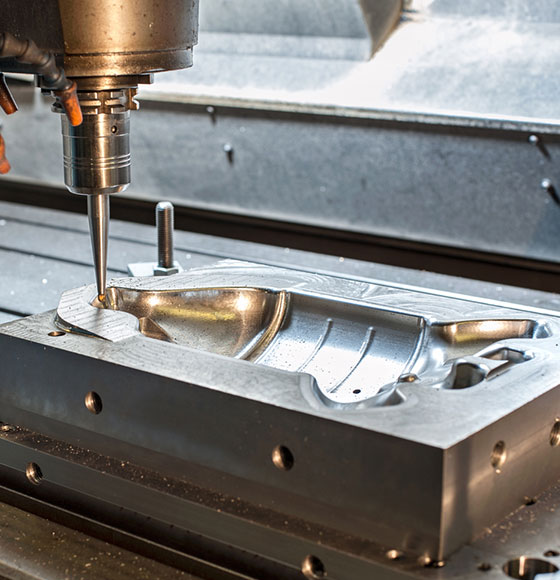

The natural wear and tear of any kind of material can eventually cause an insert to fail. This can happen to any material. This process is analogous to how the sharpness of the edge gradually diminishes over the course of time.

It is possible for normal flank wear to occur when zinc alloy die castings or materials that have been work-hardened contain hard micro-inclusions because the inclusions can cut into the insert. This wound will be visible across the entire length of the flank. Sometimes the cutting edge will get scratched by the metal on the zinc alloy die casting, which will give the impression that the wear scar on the blade is much larger than it actually is. This is due to the fact that the cutting edge is of a much higher hardness than the metal itself.

It is essential to choose the hardest insert material grade that will not chip and to make use of the lightest cutting edge to lessen the amount of cutting forces and friction in order to reduce the rate at which normal flank wear occurs over time. This can be accomplished by lowering the amount of time the insert is in use. These two actions are both things that can be done to cut down on the amount of time it takes for normal flank wear to occur.

The signs that indicate normal wear are the same as those that indicate normal wear; rapid flank wear does not leave the same telltale signs as normal wear does. To address the issue of rapid flank wear, it is necessary to choose a grade of carbide insert material that is resistant to wear, is of a higher strength, or is coated. Reducing the cutting speed is another extremely effective strategy; however, it is not appropriate for production die casting company needs because it will have a negative impact on the processing cycle of zinc alloy die castings. Production needs must be met by strategies that are appropriate for production. These processes are typically carried out at a frenetic pace the vast majority of the time.

On the surface of the planet, craters form as a consequence of the interaction of two types of wear: abrasive wear and dispersive wear. This occurs due to the fact that the workpiece itself is the source of the heat that is generated in the chips. This is going to take place China die casting manufacturer in the not too distant future. The cutting zone is where this process is driven by a confluence of chemical affinity, high pressure, and high temperature. These three factors work in tandem to propel the process forward. Chipping is another potential outcome of this situation. Built-up edge can also be identified by the presence of shiny materials on either the top or the flank of the cutting edge. This can be done on either side of the edge.

The natural wear and tear of any kind of material can eventually cause an insert to fail. This can happen to any material. This process is analogous to how the sharpness of the edge gradually diminishes over the course of time.

It is possible for normal flank wear to occur when zinc alloy die castings or materials that have been work-hardened contain hard micro-inclusions because the inclusions can cut into the insert. This wound will be visible across the entire length of the flank. Sometimes the cutting edge will get scratched by the metal on the zinc alloy die casting, which will give the impression that the wear scar on the blade is much larger than it actually is. This is due to the fact that the cutting edge is of a much higher hardness than the metal itself.

It is essential to choose the hardest insert material grade that will not chip and to make use of the lightest cutting edge to lessen the amount of cutting forces and friction in order to reduce the rate at which normal flank wear occurs over time. This can be accomplished by lowering the amount of time the insert is in use. These two actions are both things that can be done to cut down on the amount of time it takes for normal flank wear to occur.

The signs that indicate normal wear are the same as those that indicate normal zinc die casting manufacturer wear; rapid flank wear does not leave the same telltale signs as normal wear does. To address the issue of rapid flank wear, it is necessary to choose a grade of carbide insert material that is resistant to wear, is of a higher strength, or is coated. Reducing the cutting speed is another extremely effective strategy; however, it is not appropriate for production needs because it will have a negative impact on the processing cycle of zinc alloy die castings. Production needs must be met by strategies that are appropriate for production. These processes are typically carried out at a frenetic pace the vast majority of the time.

On the surface of the planet, craters form as a consequence of the interaction of two types of wear: abrasive wear and dispersive wear. This occurs due to the fact that the workpiece itself is the source of the heat that is generated in the chips. This is going to take place in the not too distant future. The cutting zone is where this process is driven by a confluence of chemical affinity, high pressure, and high temperature. These three factors work in tandem to propel the process forward. Chipping is another potential outcome of this situation. Built-up edge can also be identified by the presence of shiny materials on either the top or the flank of the cutting edge. This can be done on either side of the edge.

Cutting edge deformation is included among the traces of edge deformation even though the processed workpiece does not meet the dimensional specifications that were specified. In each of these methods, the application of an appropriate coolant is an absolutely necessary step. There is a possibility that notch wear on the tool will occur if the die casting mould rough zinc alloy die casting surface abrades and scores deeply into the cutting zone. Surfaces that have been cast, oxidized, work-hardened, or are irregular, as well as those that have the potential to cause notch wear, are all examples of potential perpetrators.

In spite of the fact that abrasive wear is the most common cause of damage in this part of the world, there is still the possibility of chipping occurring in this region. When working with superalloys, it is best to increase the cutting speed while simultaneously slowing down the feed rate. In addition, increase the grinding at the depth of cut in a cautious manner in order to prevent the accumulation of chips.

Built-up edge can be controlled by increasing the cutting speeds and feeds, using inserts with nitride coatings, making strategic use of coolant, and using inserts with force-reducing geometry and/or smooth surfaces. Other ways to manage built-up edge include using inserts with force-reducing geometry and/or smooth surfaces. Utilizing inserts with force-reducing geometry and/or smooth surfaces are two additional methods that can be utilized to manage built-up edge. During the machining of powder metallurgy (PM) materials, for example, which are intended to purposefully leave a porous structure on the part, this phenomenon can sometimes appear in locations that are completely unexpected. This can be the case when the material is machined. Chipping can be prevented by ensuring that the machine is properly set up, minimizing warping, making use of ground inserts, controlling built-up edge, selecting an insert material grade that is more durable, and selecting either a cutting edge geometry that is stronger or a cutting edge geometry that is more durable. The failure of a thermomechanical system can be brought on by sudden shifts in temperature that are particularly severe, as well as by abrupt shocks to the system's mechanical components. The process of intermittent turning of high-volume parts must also take into consideration the possibility of thermomechanical failure.

Thermomechanical failure can be avoided by making proper use of coolant, or if it is desired to completely eliminate this failure in the machining process, by making use of more impact-resistant material grades and geometries that reduce heat generation and reduce feed rates. Alternatively, the failure can be completely eliminated in the machining process by using higher feed rates. Both of these approaches can be utilized to their full potential in order to eradicate this failure entirely. Either one of these two strategies could be used to ensure that the machining process is carried out without incident and without the risk of the previously described failure occurring. Both high speeds and high feeds have the propensity to produce a significant amount of heat for the environment in which the work is being done. If there is an abnormally high amount of heat, the carbide bond or the cobalt in the insert might become flexible. This could happen for either of these two elements. When the insert is subjected to stress, this sinking of the tip will occur.